Steam Transfer Hose Assemblies & Fittings

Our last post pointed out the three reasons why you should use PTFE lined hose assemblies in your manufacturing processes. In this post we will cover hoses that are used for steam transfer and things to think about when dealing with steam transfer hoses.

What are steam transfer hoses used for?

Steam can be wet saturated steam, dry saturated steam, or superheated steam, which is also known as "dry steam." In some cases, steam hoses are made of a thick rubber that is designed to transfer steam from one place to another. PTFE steam hoses and flexible metal steam hoses have proven to be more durable. Stainless Steel Braided hose can withstand higher temperatures and can handle higher pressures. PTFE steam hose assemblies maintain their flexibility when steam transfer is required.

Due to the nature of steam and the temperature resistance needed, high-quality steam hoses are an essential part of the manufacturing process. Used in various industries, especially the food & beverage industry, steam hose assemblies and sanitary fittings need to meet FDA requirements. Other industry applications include oil refineries, chemical plants, shipyards, and tire manufacturing. The pulp and paper industry relies on steam hoses to control the elimination of steam build-up during manufacturing. Likewise, building control systems are another place steam hoses are needed for effective building operations.

What are the best hoses for steam?

Stainless Steel Braided PTFE steam hoses can withstand temperatures up to 450 degrees F and flexible metal hoses can take on temperatures up to 1500 degrees F. Both types of hoses can handle higher pressure than the typical EPDM steam hoses. High-quality PTFE steam hoses & fittings can keep your manufacturing processes running longer and lower your production cost while increasing output and profitability. The construction and fabrication process of PTFE steam hose assemblies makes all the difference.

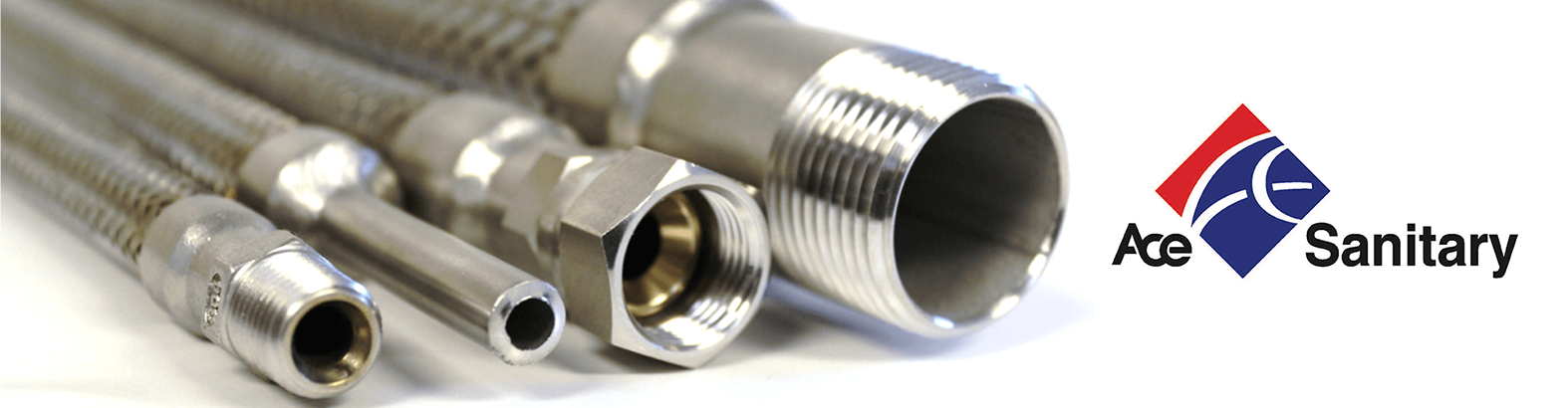

When it comes to durability, typical rubber steam hoses do a decent job of standing up to weather, ozone, and abrasion. PTFE and flexible metal steam hoses are the best choices because of the construction. These hoses have a stainless steel braid reinforcement which makes them durable. The braid also protects the hose against tougher conditions and increases its lifespan. Plus, they have better flexibility than rubber steam hoses, which allows for wide variety of applications. With sanitary fittings, it is resistant to deposit build-ups and is non-absorbent. Coupling with a fire sleeve or insulated wrap, the PTFE steam hose has added insulation and protects the operator.

If your process requires steam transfer hose assemblies, let Ace Sanitary and our expert team help choose the right hose for your application. We can answer your questions and provide a quote for custom steam hose assemblies, Contact us Today.