About Our MCB Products

Select our flexible all-metal hose for your applications that require flexible hose assemblies for more extreme temperatures, with similar pressures to our PTFE hose assemblies.

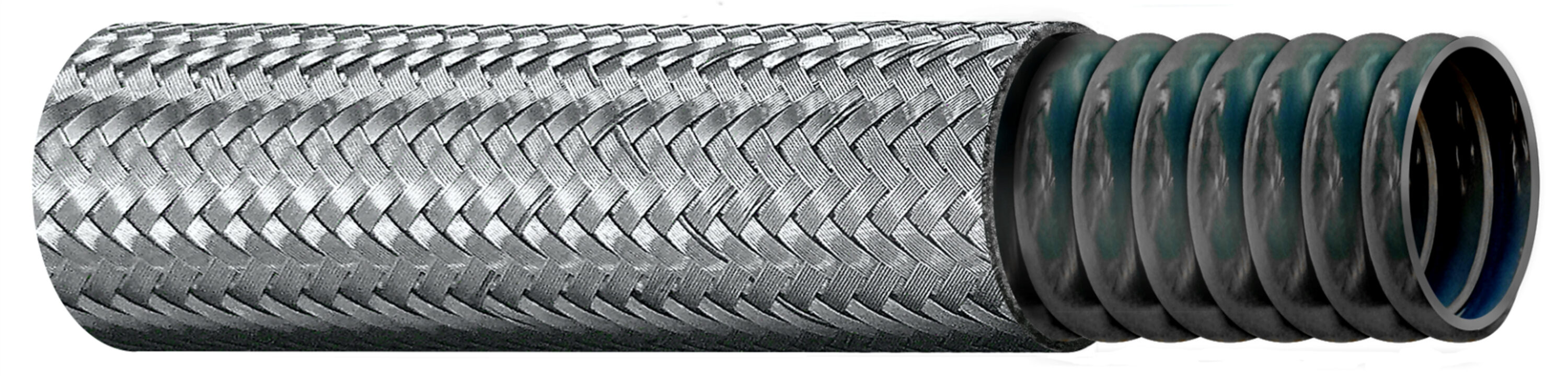

Ranging from 1/4” up to 12” in diameter, the flexible metal hose is constructed with a corrugated stainless steel liner and is sold alone or reinforced with one or more outer covers of braided stainless steel to meet your process application requirements.

Varying metal strengths of the corrugated liner and additional layers of braiding are available for flexible metal hose. Metal hoses are an ideal option when you need a high-temperature hose or flexible hose. These high-temperature hoses are used in applications, from Cryogenic up to 1300° F, at varying pressures.