Prior to Installation

Inspect hose completely for signs of obvious damage. Possible damage may include cuts to cover, kinking, broken braids and crushing. This damage can reduce hose life and pressure rating.

Inspect hose completely for signs of obvious damage. Possible damage may include cuts to cover, kinking, broken braids and crushing. This damage can reduce hose life and pressure rating.

Hose should be application specific. Review materials, pressures, chemical compatibility, temperature, and environment to ensure proper selection of hose.

Failure of hose will occur when hose is bent (Fig. 1) beyond the minimum bend radius. Bend radii are given for individual products and sizes. The bend radius values must be observed (measure to inside radius of fluoropolymer-lined hose and the centerline for stainless steel metal hose) for hoses to be installed properly. Occasionally, vacuum and pressure ratings are based on not to exceed 2% minimum bend radius. The manufacturer should be contacted for specific hose rating and data.

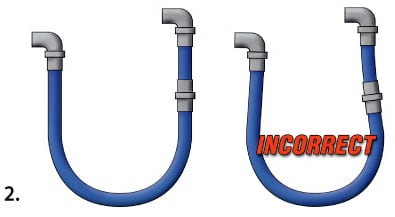

Restrict hose movement to a single plane (Fig. 2) to minimize resultant twisting or torque. Within the bending plane is where flexing should occur. Stress fatigue increases with excessive bending of hose.

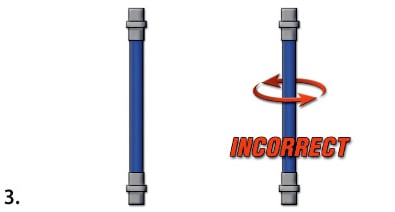

Axial or twisting movement (Fig. 3) should be eliminated. The likelihood of leakage or failure increases for hoses that are twisted (torqued) during assembly. Floating flanges or swivel-type fittings (i.e., JIC) can eliminate improper twisting.

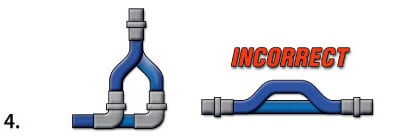

Avoid stretching or compressing the hose (Fig. 4) along its longitudinal axis with in-line installation.

Motion that occurs when a hose is compressed along its longitudinal axis. Axial motion is only applicable in very short lengths of annular hose only. Fluoropolymer lined hose should not be subjected to axial motion.

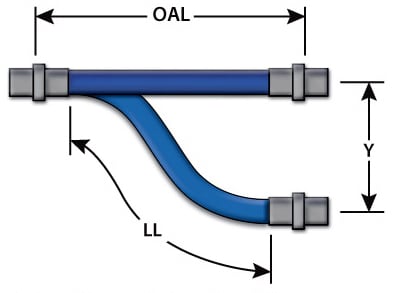

Motion that occurs when one end of the hose is defected in a plane perpendicular to its longitudinal axis with the ends remaining parallel. In offset applications where motion is repeated, the offset should never exceed 25% of the minimum bend radius. To calculate the required live length to achieve a desired offset, use the following calculations:

Note: Where offset motion “Y” occurs on both sides of hose centerline, the hose live length should be based on total travel, or 2Y. The modified calculation will be:

LL = √ 12YR + (2Y)2

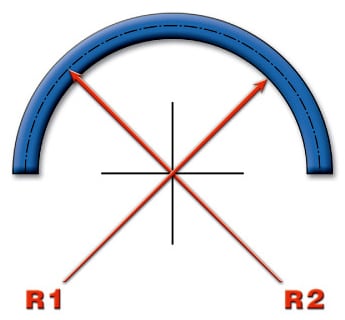

Bend Radius (fluoropolymer hose and all rubber hose)

The radius of a bent section of hose measured to the innermost surface of the curved portion (R1)

Bend Radius (metal hose)

The radius of a bent section of hose measured to the hose centerline (R2), Minimum Bend Radius

Minimum Bend Radius

The smallest radius at which a hose can be used

Force to Bend

The amount of stress required to induce bending around a specific radius, a measure of stiffness

Maximum Rated Working Pressure

The maximum pressure hoses should be subjected to on a continuous basis

Maximum Rated Test Pressure

The maximum rated pressure is multiplied by 150%

Nominal Rated Burst Pressure

The average pressure at which the core of braid will rupture at ambient temperature

Pressure / Temperature Correction

Hose pressure capabilities decrease as the temperature increases. Consult factory to determine pressure rating at elevated temperatures

Flexibility and minimum bend radius are important factors in hose design and selection if it is known that the hose will be subjected to sharp curvatures in normal use. When bent at too sharp an angle, the hose may kink or flatten in the cross-section. The reinforcement may also be unduly stressed or distorted and the hose life thereby shortened.

Adequate flexibility means the hose should be able to conform to the smallest anticipated bend radius without over-stress. The minimum bend radius is generally specified for each hose in this catalog. This is the radius to which the hose can be bent in service without damage or appreciably shortening its life. The radius is measured to the inside of the curvature.

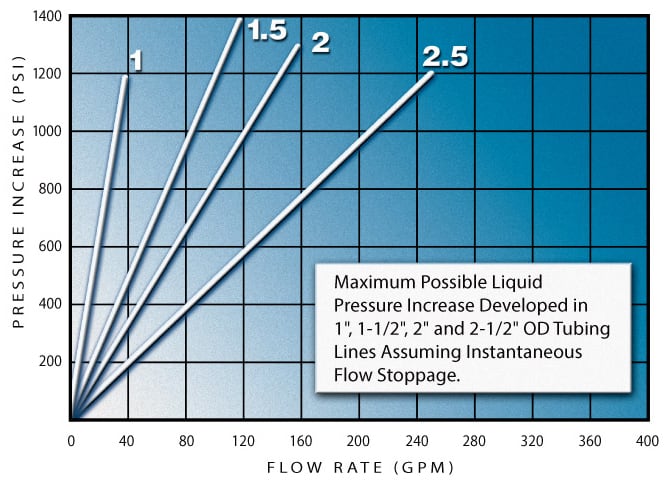

Due To Instantaneous Pressure Increase: