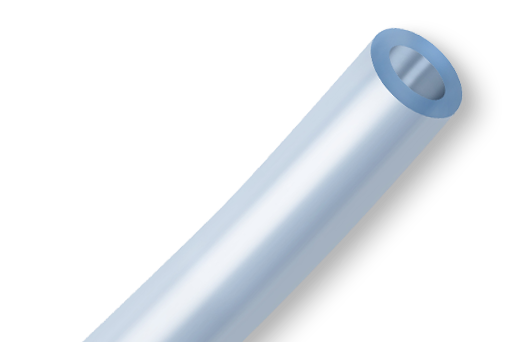

Single-use tubing is often made from flexible materials such as various types of elastomers (e.g., Silicone), TPE, TPC, and PVC (e.g., polyethylene, polyurethane). The choice of material depends on factors like chemical compatibility, flexibility, and regulatory requirements.

Single-Use Tubing

Tubing specialized for Pharma and Biotech Applications

Single Use Tubing Assemblies from Ace Sanitary

Single-use tubing has become integral to modern bioprocessing and pharmaceutical manufacturing due to its convenience, sterility, and operational efficiency benefits. Ace Sanitary also provides a variety of tubing options based on the needs of the application such as TPE, TPV, and PVC.

Ace Sanitary offers custom single use assemblies engineered for highly regulated applications, including pharmaceutical and biotech processes. These solutions include single-use molded silicone tubing built to order with no minimum order quantities.

Cleanroom Manufacturing

Providing cleanroom USP Class VI tubing directly from our facility provides our customers with the quality and low lead times they expect. Ace Sanitary offers a broad range of tubing options backed by Sterility Assurance and compendia testing. Our platinum-cured silicone tubing is made from high-quality USP Class VI silicone that has been cured using platinum as a catalyst, ensuring a pure and contaminant-free material. Our tubing meets the critical demands of the medical, pharmaceutical, research, biotech, and diagnostic industries.

Fast lead Times, Expedited Quoting, No Minimum Order Quantity

Promo Form

"*" indicates required fields