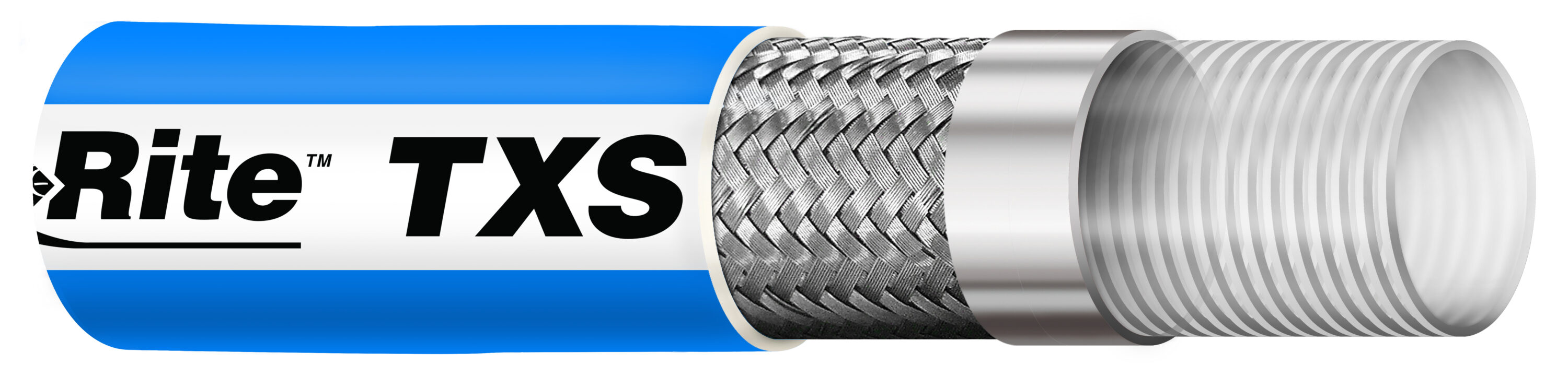

TXS is made for maximum flexibility, hygienic performance, and durability in critical applications. It excels where product viscosity, flow rate, contamination risk, turbulence, and cleanability are key concerns. Ideal for ultra-sanitary environments in the food, biotech, pharmaceutical, and cosmetic industries, TXS is the go-to choice when a non-convoluted, high-flex hose is essential for dynamic use and clean-in-place (CIP) or steam-in-place (SIP) processes.

This hose features an exterior convoluted design with stainless steel braid reinforcement and paired with an EPDM cover.