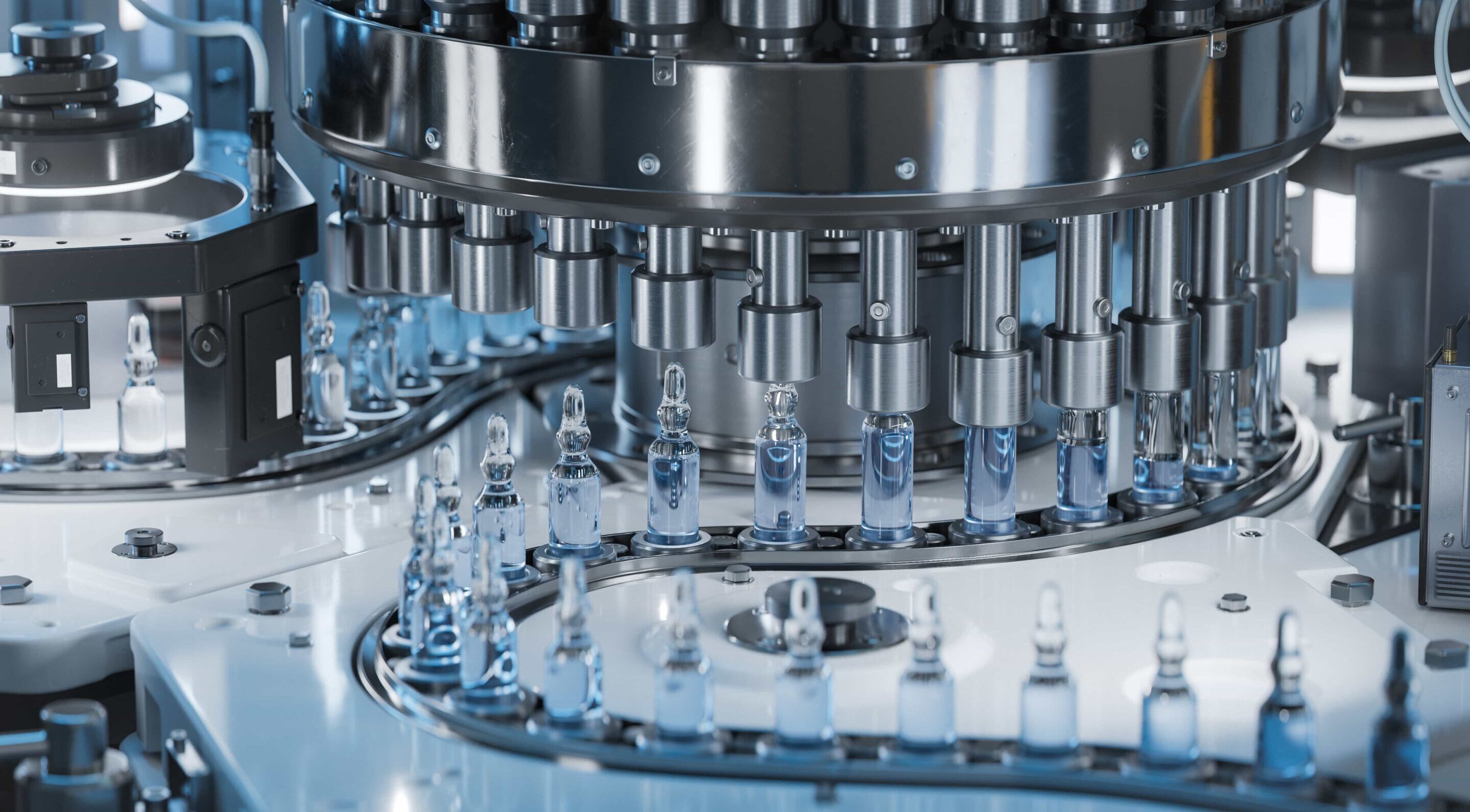

The biopharmaceutical industry is built on precision, purity, and consistency. From upstream cell culture and fermentation to downstream purification and final fill operations, manufacturers must maintain sterile conditions and reliable fluid transfer at every stage. End users include pharmaceutical manufacturers, biotechnology companies, contract development and manufacturing organizations (CDMOs), and research labs. Each relies on high-performance single-use and multi-use systems to streamline production while meeting strict regulatory expectations.

Hoses and assemblies in biopharmaceutical manufacturing must meet the industry’s most stringent standards for safety and compliance. Materials are required to meet USP and ISO requirements for biocompatibility. In some cases, ISO 11137 sterility, and extractables testing is required to ensure purity and patient safety. Many products must be manufactured in cleanroom environments, typically ISO Class 7 or higher, and offer complete material traceability. Additional requirements include sterility assurance, resistance to common bioprocess fluids, compatibility with steam or CIP processes, and flexibility to support both single-use and closed-system designs. With supply chain resilience more important than ever, domestic production and short lead times are also critical to success.

Ace Sanitary is uniquely positioned to meet these demands with a full portfolio of single-use products and multi-use hose solutions. Our single-use bioprocessing assemblies are manufactured and assembled in our Cincinnati facility under ISO Class 7 cleanroom conditions. These assemblies are backed by rigorous testing, sterility assurance, and full USP compliance, ensuring reliable performance in even the most demanding applications.

Our proprietary Flex-Rite™ platinum-cured silicone hoses are extruded in cleanroom environments to deliver seamless construction, superior purity, and consistency. For applications requiring long-term durability, our multi-use silicone and PTFE hoses extend compatibility into processes that demand higher resistance to steam sterilization, extended service life, or exposure to aggressive cleaning regimens. With robust quality systems that include ISO 11137 sterility programs, extractables and biocompatibility testing, and complete material traceability, Ace Sanitary provides products that support both compliance and performance.

Ace Sanitary is more than a hose supplier—we are a partner in advancing safe and efficient biopharmaceutical production. Our expertise in cleanroom manufacturing and regulatory compliance ensures every assembly is designed for precision and reliability. We deliver with speed, offering rapid turnaround on standard products, no minimum order requirements, and custom-engineered solutions to fit complex flow paths. And we emphasize simplicity, with straightforward solutions, responsive service, and a commitment to making your supply chain more resilient and easier to manage.

From single-use assemblies to multi-use silicone and PTFE hoses, Ace Sanitary delivers a comprehensive range of solutions designed for the purity, safety, and performance required by the biopharmaceutical industry.

Find out more about Ace Sanitary’s Class 7 Cleanroom capabilities.