The Importance of 3A Hose Assemblies

What is the Importance of 3A Hose Assemblies?

In our last blog, we explained the features that comprise a standard Sanitary Hose and how certain FDA certifications can designate a Food Grade Hose. In this post, we will give an introduction to 3A, the benefits of your equipment displaying the 3A symbol, and will uncover the elements of 3A standards for hose assemblies. 3A Standards, a platinum-level set of guidelines, are important to understand because they provide a high standard for the hygienic qualities of the equipment used to produce products that we all use.

What is 3A?

The first standards for hygienic equipment design were introduced in 1920 and ultimately became known as 3A Standards. Presently, 3A Standards represent Equipment Fabricators, Food Processors, and Regulatory Bodies. 3A SSI upholds a wide range of design criteria for equipment and processing systems. These criteria are developed using a consensus system based on ANSI (American National Standards Institute) requirements that support acceptance by USDA, FDA, and other state regulatory authorities.

The 3A symbol is licensed on a voluntary basis, subject to the requirements of the organization. 3A Sanitary Standards are widely recognized and implemented across many markets for the safe and reliable production of all types of food and dairy products. The 3A Sanitary Standards are widely employed to reduce or eliminate the risk of contamination in food and dairy products. Think of 3A Standards as a set of strict guidelines that ensure cleanliness for the equipment used to produce products that we consume.

Benefits of Your Equipment Displaying the 3A Symbol

Displaying the 3A symbol yields various perks for those who adhere to the 3A equipment standards. Some of these benefits include:

- Providing verification of proper function of equipment and that the equipment is reliably and consistently clean on an allergen and microbial level

- That the Designs and Equipment produced have been reviewed by an independent inspector (CCE) for conformance

- 3A conforming and authorized equipment provides for quick regulatory acceptance

3A 62-02 Sanitary Standards for Hose Assemblies

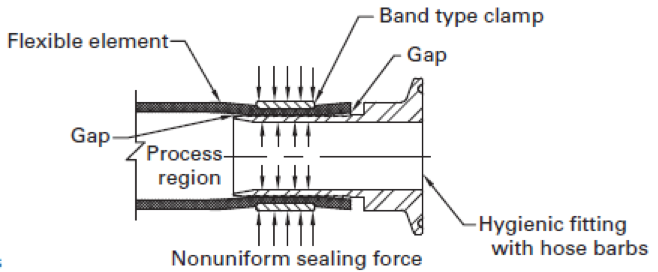

Compliance to 3A 62-02 Standards covers materials of construction, or the materials used to produce equipment, as well as fabrication and joining methods for the given equipment. Both of these areas are critically important to ensuring that typical CIP (Clean-in-Place) procedures are effective in preventing microbial contamination. As a result, permanently attached hose fittings on one or both ends of multiple-use, smooth-bore hoses are covered by the Standards, while fittings attached with band clamps are specifically excluded. These fittings have multiple areas in which bacteria can enter empty spaces, thusly jeopardizing the purity of the assemblies. The diagram shown at the right illustrates the issues clamped connections present with regard to their ability to be cleaned.

Furthermore, other hose assemblies that are not covered by the 3A Sanitary Standards include hose assemblies that utilize band, strap, or worm-gear clamps or manually tightened fitting devices normally used to secure removable fittings, which are not designed for CIP cleaning.

Additionally, the standards do not cover hose assemblies with a convoluted or a corrugated inner surface, hose assemblies with exposed metal overbraid exterior surfaces, or hose assemblies with a hose ID (Inside Diameter) of less than 0.75 in.

Equipment that cannot be properly cleaned due to dead legs or areas of entrapment, provides a breeding ground for bacteria. It is imperative to avoid such contamination in order to produce consistent flavor and quality in the products produced, while also reducing wasteful and expensive spoilage.

Refer to the diagram to the right to explore our patented, 3A certified fitting and the special features that make our assemblies unique!

You can also learn more about our 3A certified assemblies by clicking here!